Researchers create active material out of microscopic spinning particles

by Jared Sagoff

At the atomic level, a glass of water and a spoonful of crystalline salt couldn't look more different. Water atoms move around freely and randomly, while salt crystals are locked in place in a lattice. But some new materials, recently investigated by researchers at the U.S. Department of Energy's (DOE) Argonne National Laboratory, show an intriguing propensity to sometimes behave like water and sometimes like salt, giving them interesting transport properties and holding potential promise for applications like mixing and delivery in the pharmaceutical industry.

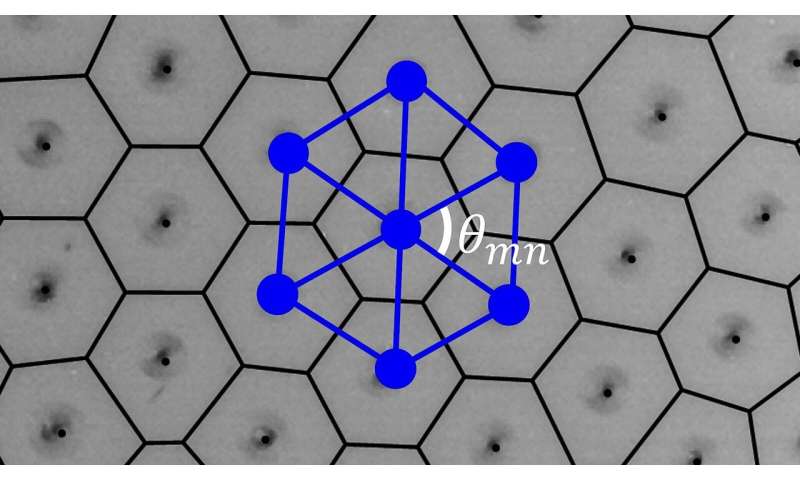

These so-called active materials contain small magnetic particles that self-organize into short chains of particles, or spinners, and form a lattice-like structure when a magnetic field is applied. "Active materials need an external energy source to maintain their structure," said Argonne materials scientist Alexey Snezhko, an author of the study.

Unlike in previous experiments involving active materials, which looked at particles that demonstrated linear motion, these new spinners acquire a handedness—like right- or left-handedness—that causes them to rotate in a specific direction.

This twirling rotation of the suspended self-assembled nickel spinners creates a whirlpool-like effect, in which different particles can get sucked in to the vortices created by their neighbors. "The particles don't move on their own, but they can be dragged around," Snezhko said. "The interesting thing is that you can have these very quickly rotating structures that give the appearance of a yet larger system that is still, but it remains quite active."

As the particles start to come together, the whirlpools created by the spinning motion—in conjunction with the magnetic interactions—pull them even closer, creating a fixed crystalline-like material, even as the spinners still rotate.

The Argonne researchers wanted to know how a non-spinner particle would be transported through the active lattice. According to Snezhko, the rapid whirling of the spinners creates the ability for these other cargo particles to move through the lattice much more quickly than they would through a normal material. "In regular diffusion, the process of getting a particle from one side of the material to the other is temperature-dependent and takes a much longer period of time," he said.

The transport of a non-spinner particle is also dependent upon the spacing between the spinners. If the spinners are located sufficiently far apart, the non-spinner particle will travel chaotically between different spinners, like a raft traveling down a series of whitewater rapids. If the particles in the lattice come closer together, the non-spinner particle can become trapped in an individual cell of the lattice.

"Once the particle comes within a cell through its own chaotic motion, we can modify the field so that the lattice slightly shrinks, making the probability of the particle to leave that location in the lattice very low," Snezhko said.

The material also showed the ability to undergo self-repair, similar to a biological tissue. When the researchers made a hole in the lattice, the lattice reformed.

By looking at systems with purely rotational motion, Snezhko and his colleagues believe that they can design systems with specific transport characteristics. "There are many different ways for getting an object in a material from point A to point B, and this type of self-assembly could be tailored for different dynamics," he said.

A paper based on the study, "Reconfigurable structure and tunable transport in synchronized active spinner materials," appeared in the March 20 issue of Science Advances.

More information: Koohee Han et al, Reconfigurable structure and tunable transport in synchronized active spinner materials, Science Advances (2020). DOI: 10.1126/sciadv.aaz8535

Journal information: Science Advances

Provided by Argonne National Laboratory