Indonesia looks to domestic innovations to tackle COVID-19

by Made Anthony IswaraIndonesia is striving to tackle the COVID-19 outbreak with domestically produced innovations, but researchers say the government may face roadblocks in the mass production of such products because of the absence of pro-innovation policies.

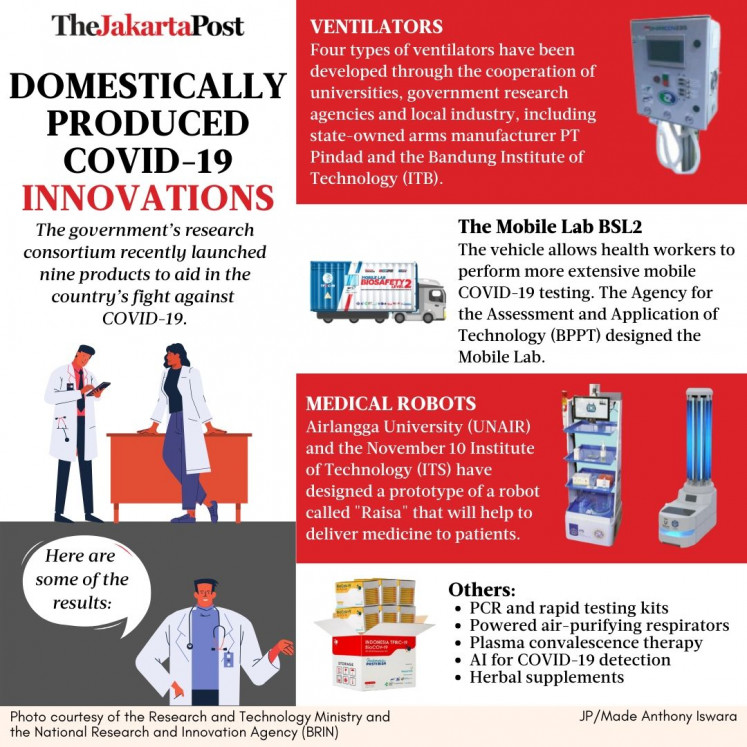

The government’s research consortium on Wednesday launched nine products, including ventilators, a type of polymerase chain reaction (PCR) test and rapid antibody testing kits, in an effort to overcome the shortage of critical medical equipment in Indonesia’s fight against COVID-19.

The nine inventions were the result of a consortium formed on March 26 by the Research and Technology Ministry and the National Research and Innovation Agency (BRIN) to develop innovations to fight the outbreak. The program involves universities, government research agencies and local industries – both private and state-owned – including defense firms such as state-owned arms manufacturer PT Pindad.

President Joko "Jokowi" Widodo said that the world was competing to address the COVID-19 epidemic and that Indonesia "must answer it with concrete innovations and concrete work".

"These products should not remain in the laboratory only or be limited to prototypes; mass production must follow to fulfill domestic needs and to possibly export [the products] to other countries," he said.

Researchers, who have long criticized the government for overlooking how important research is for the country’s development, are praising the efforts to include research in the ongoing COVID-19 struggle. But they say the government still needs to overcome obstacles, mainly Indonesia’s dependence on imported raw materials and bureaucracy, to make innovations quickly and readily available on a large scale.

Indonesian Young Academy of Science (ALMI) secretary general Berry Juliandi said that domestically produced products such as PCR test kits and ventilators relied on imported materials for production. Some important chemicals were patented, so Indonesia would need to buy the patents before continuing with production.

"Essentially, we welcome this initiative because we are happy that we are involved in it. But we still struggle to be independent in producing raw materials to make such products," said Berry.

He recommended that the authorities relax import requirements and taxes to prevent a shortage of raw materials for mass production.

But difficulties in procuring raw materials had existed before COVID-19. In 2018, the Health Ministry noted that about 90 percent of the country’s pharmaceutical production used imported materials.

Indonesia Science Academy (AIPI) head Satryo Soemantri Brodjonegoro said producers could also face difficulties when dealing with bureaucracy as no national standards existed to regulate the new products.

He advised the Industry Ministry and the National Standardization Agency (BSN) to avoid using foreign standards as they would halt the mass production process because the products that he had seen so far had not met the international benchmark. Instead, he said, a national consensus on a feasible standard was needed to allow for swift production without sacrificing product safety.

"We must see the urgency. We have to start first and perfect the innovations later," Satryo said.

The Health Ministry's health testing center has removed its secondary requirements for innovations, such as noise levels for ventilators, after receiving the AIPI's recommendations, Satryo said.

Research and Technology Minister and BRIN head Bambang Brodjonegoro told The Jakarta Post that the recently launched products would make extensive use of local components (TKDN) and would be able to replace their imported counterparts.

The ministry said it would also push its research and development department to find substitutes for imported materials, such as reagents for PCR tests. It would also focus on using herbal ingredients rather than chemical ones for medicines to make “modern Indonesian medicines”.

Bambang said that some of the nine products had already entered production and would be ready by next month for national use.

Indonesia will start producing 100 to 300 ventilators each week starting next week, depending on production capacity. Pindad, hospital equipment maker PT Poly Jaya Medikal, electronics manufacturer PT LEN and automotive holding company Dharma Group were among those involved in the development of the four different types of ventilators.

Bambang estimated that the country would have a sufficient supply by next month and would be able to distribute the ventilators to hospitals throughout Indonesia.

At least 10,000 domestically produced rapid testing kits are currently undergoing validity tests at several hospitals in Central Java. Bambang said that authorities planned to produce 40,000 to 50,000 rapid testing kits and PCR testing kits each by next month.

He said these innovations would offer affordable alternatives to imported ventilators and rapid testing kits, which are now expensive because of soaring global demand.

"[The expense of importing products] is what motivates researchers and innovators in the country to try to produce them on their own," Bambang said.

If you want to help in the fight against COVID-19, we have compiled an up-to-date list of community initiatives designed to aid medical workers and low-income people in this article. Link: [UPDATED] Anti-COVID-19 initiatives: Helping Indonesia fight the outbreak