Scientists find a simple solution for making ferroelectric nylon thin films

by Giulia RuzzeneAn efficient way of making ferroelectric nylon has been developed by Saleem Anwar and collaborators at the Max Planck Institute for Polymer Research in Mainz, Germany. The technique provides a starting point for the cost-efficient production of ferroelectric nylon thin films using commercially-available materials. Such films could find a wide range of applications including robotics, biomedical devices and energy harvesting.

We are all familiar with nylon as a synthetic material used for clothing, but some types of nylon have much more sophisticated applications. Nylon is composed of repeating aliphatic units connected by amides. Aliphatic compounds are open-chain materials formed by carbon and hydrogen atoms, such as methane and ethylene.

Spontaneous electric polarization

Nylon is characterized by the number of carbon atoms in the repeating aliphatic units. When this number is odd, nylon can be ferroelectric with spontaneous electric polarization. This type of nylon can therefore be used to make capacitors. Together with their mechanical properties, ferroelectricity makes odd nylons ideal candidates for a range of applications.

According to the team it is a challenge to “construct smooth, optically transparent, pinhole-free solution processed odd-nylon films that are crystallized in the ferroelectric phase”.

The team turned to solution processing, which is a low-cost technique that can be performed at room temperature. Nylons are insoluble in most common solvents, so the first step in the solution processing of nylons is to find the right solvent. Anwar and colleagues found that a mixture of trifluoroacetic acid (TFA) and acetone has the right properties to be used in solution processing of low number odd nylon thin films.

Desired crystalline phase

Nylons can solidify in different crystalline phases, and ferroelectricity occurs in only one of these possible phases. This is a phase in which the unorganized hydrogen-bonded chain structure enables the polarization of the compound. Before this study this ferroelectric phase of odd nylon had never been created by solution processing at room temperature.

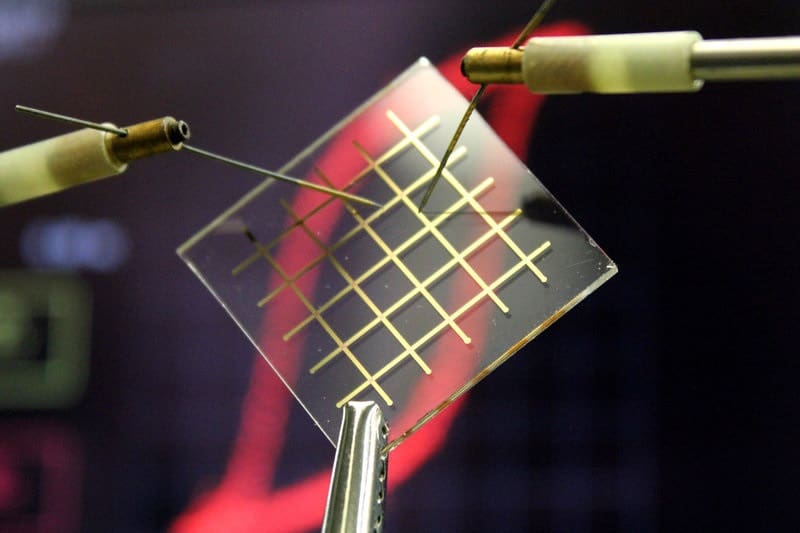

The thin films of nylon are made by spin-coating the solution on a glass substrate. The samples are then placed in high vacuum for solution quenching, which freezes the components in the unorganized phase and removes the remaining solvent.

The authors compared the performance of a nylon-11 ferroelectric capacitor with a capacitor made of conventional ferroelectric polymers. The test focused on the ability of the capacitor to retain the polarized state when it is subjected to continuous stress cycles. The nylon-11 capacitor outperformed the conventional one during a million stress cycles.

The technique is described in Science Advances.